I. Overview

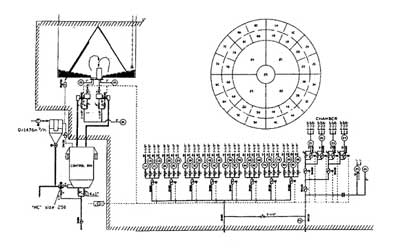

The CP library is a new type of raw meal homogenization library introduced by our company from Germany BMH, which has the characteristics of low power consumption and good homogenization effect. The homogenization principle of the CP warehouse is that the raw materials on the top of the warehouse are distributed evenly through 8 chutes, and the raw materials of different periods are distributed horizontally in the warehouse. The design of the aeration system at the bottom of the warehouse is more in line with the fluidity of the raw materials after inflation, showing a radial oblique direction. Distribution, the annular zone is generally divided into 8 zones, which are inflated in turns every 5 minutes. The raw materials in the aeration zone are discharged into the central area due to looseness and airflow. The raw materials in different layers in the warehouse are vertically cut to realize the homogenization of the raw materials. , The raw meal at different times enters the central area and then enters the body to mix and homogenize strongly, so as to achieve the ideal homogenization effect.

2. Technical parameter table

3. CP library schematic diagram

4. the characteristics of the electric control pneumatic flow valve and pneumatic switch valve in the CP raw meal homogenization warehouse

1. The labyrinth type sealing box is added with imported woolen fabric packing, so it has perfect sealing performance;

2. The valve body and valve plate are made of special foreign wear-resistant materials, which are wear-resistant, lightweight, and flexible in control. They are almost maintenance-free during their service life;

3. There are three control modes: manual, on-site control and central control, with 4~20mA signal input and output interfaces, and the flow adjustment is uninterrupted and continuous adjustment;

4. There is a safety coupling on the valve for manual operation. Driven by a pneumatic cylinder, with a pneumatic position control system. The remote positioner is a current loop, the position setting signal is 4-20mA, the angular position feedback signal is 4-20mA, and the power supply voltage is 24V. In the event of a power failure, the valve will automatically move to the "off" position; the fast closing time is ≤3 s/time, and the opening adjustment time is about 45s; the air pressure required to be controlled is 0.6 MPa ± 1 MPa, so that the traditional flow control valve Combines with pneumatic on-off valve.

5. The cylinder is used as a pneumatic drive actuator. Its drive cylinder is a rack-and-pinion structure, which can run quickly in any forward and reverse directions and eliminates the hysteresis and mechanical inertia caused by the infrequent forward and reverse rotation of the electric drive, so as to achieve real-time Tracking adjustment, no mechanical failure at all. Pneumatic drive has high overload resistance and high output torque, almost maintenance-free during its service life, and low energy consumption and cost.

6. The flow adjustment of the valve adopts a Siemens positioner, which is non-contact type, directly connected with the valve shaft, and has no transmission mechanism, so the positioning accuracy and reliability are high; the control accuracy can reach 1%.