The IBAU homogenization library adopts the continuous homogenization technology of Hamburg, Germany. There is a mixing silo on the outside, a large cone is set at the bottom of the silo, the weight of the raw material in the silo is transmitted to the wall of the silo through the cone, the annular space at the bottom of the silo is divided into 6 aeration zones inclined to 10°, and each zone is equipped with a variety of specifications for aeration. box. During aeration and unloading, the raw meal is sent to a radially arranged inflatable box, and then sent to the mixing chamber at the bottom of the warehouse by the air chute through the discharge port at the lower part of the cone. When unloading, the raw meal cuts the horizontal material layer during the top-down flow process to produce gravity mixing. After entering the mixing chamber, it is further homogenized due to continuous aeration and stirring. The average value can reach 6-8, and the power consumption is 0.1-0.2kwh/t raw meal.

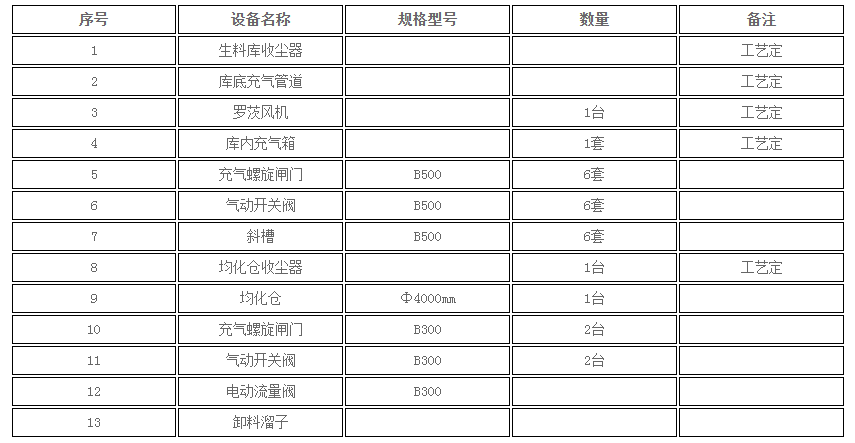

Technical Data Sheet