1. Working principle of piston air cannon

The air cannon uses the principle of air pressure balance. The compressed air is first stored in the steel gun body. When the air pressure in the gun body reaches 0.4-0.8Mpa, it is operated by electric (or manual) pneumatic components to cut off the compressed air flow and open it. At the exhaust port of the solenoid valve, the piston instantly forms a pressure difference between front and rear, forcing the piston to move back, and opening the exhaust port, so that the compressed air is sprayed at a supersonic speed in a predetermined direction when the compressed air is used. Flush the material blockage area to overcome the static friction of the material, so that the arched or frozen material can resume gravity flow again, so that the blockage is eliminated, and the work is continuous;

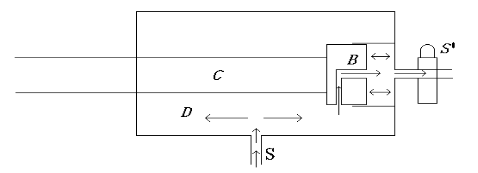

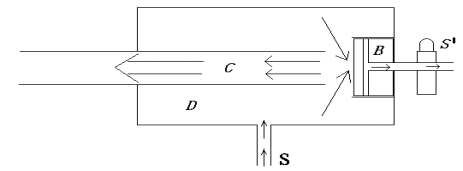

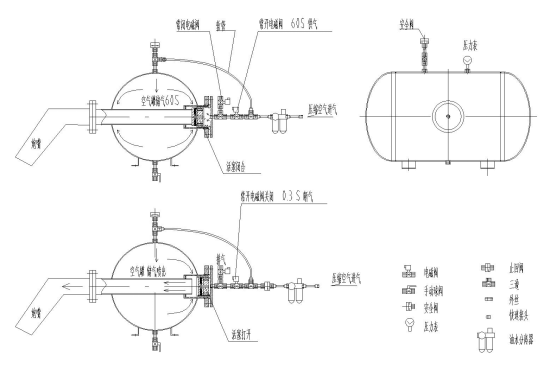

S air inlet pipe S’air gun special fast exhaust valve B piston C exhaust pipe D cylinder

1, open the intake valve, air through the S into the gun body, because the piston through the reset device always closed the exhaust port, the piston back and gun body interlinked, produce air pressure balance.

2, air gun special fast exhaust valve power work, open the exhaust hole O, cylinder in the air smoothly discharged. There is no pressure in the cylinder liner, and the pressure difference is formed under the pressure of the compressed air in the cylinder. The piston rapidly returns to the right, and the exhaust pipe C is opened. The compressed air in the cylinder is instantly discharged and the material is shocked.

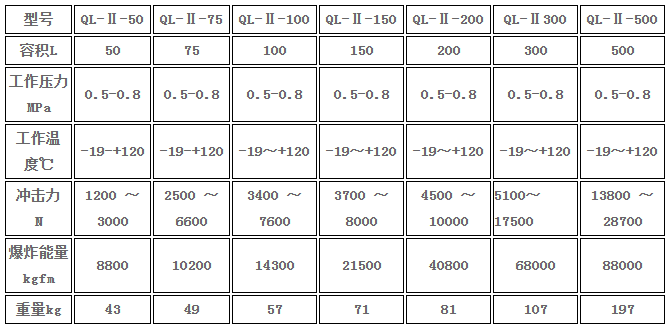

2. piston type air gun selection parameters

3.piston type air gun assembly diagram