1. Function overview:

QL- I air cannon is the model developed by this company blocking flow aid device, it can effectively prevent, reduce and remove the silo (reservoir) in material arching, adhesion and blockage, obvious for small granular or powdered materials, can be widely used in building materials, grain, steel, electricity, coal, the fertilizer industry has bin (bank) factory.

2. Features of this machine

1, easy to operate, just a little press, you can safely spray or use advanced micro-computer controller design, centralized control can be achieved fully automatic operation.

2, the explosive force is strong, according to the instantaneous release of gas volume expansion of the shock wave directly on the blockage of materials, therefore, its high energy utilization, strong detonation force.

3, safe and reliable, its main containers according to the national pressure standards for the design and manufacture. The gas explosion is carried out in a closed warehouse, the device is firm and fixed on the wall of the silo, so the risk is minimal, safe and reliable.

4, low energy consumption. The amount of compressed air required for air gun clearance is much less than that of conventional air blast cleaning. Artificial jet can be selected according to the requirement, which greatly reduces the energy loss.

5, the same volume of air gun detonation force depends on the gas release rate (release time). The capacity of the air gun is the same as that of the jet orifice, and the gas release time is basically the same, so the detonation force is proportional to the volume. That is, the larger the volume, the greater the detonation force, the larger the detonation force can be obtained according to the need.

3. Main technical indicators

1,Conditions of use

Ambient temperature: -10℃-+40℃

Relative humidity: ≤90%

Altitude: ≤3000m

2,Power requirements:

Operating voltage: 380V±5%, 50Hz

Control voltage: 220 V±5%, 50Hz

Instrument voltage: analog 4-20mA

Digital quantity 220 V, 50Hz

3,Gas source requirements:

Pressure: ≥0.5MPa

Air volume: meet the explosion requirements

4,Technical indicators:

Under the above conditions, the air cannon has the following technical performance:

High temperature type: effective cleaning area of 1.5 square meters.

Normal temperature type: According to the different volume of the air cannon storage tank and the nature of the material, the cleaning area is 1.5-4 square meters.

4. Main technical indicators

The air cannon is suddenly ejected a stream of compressed air, to block the release of stored area of bulk materials, to produce instant release of compressed air volume expansion shock wave, overcome the internal friction of the material, eliminate material adhesion, get rid of the material so that the material in the arch, re flow condition.

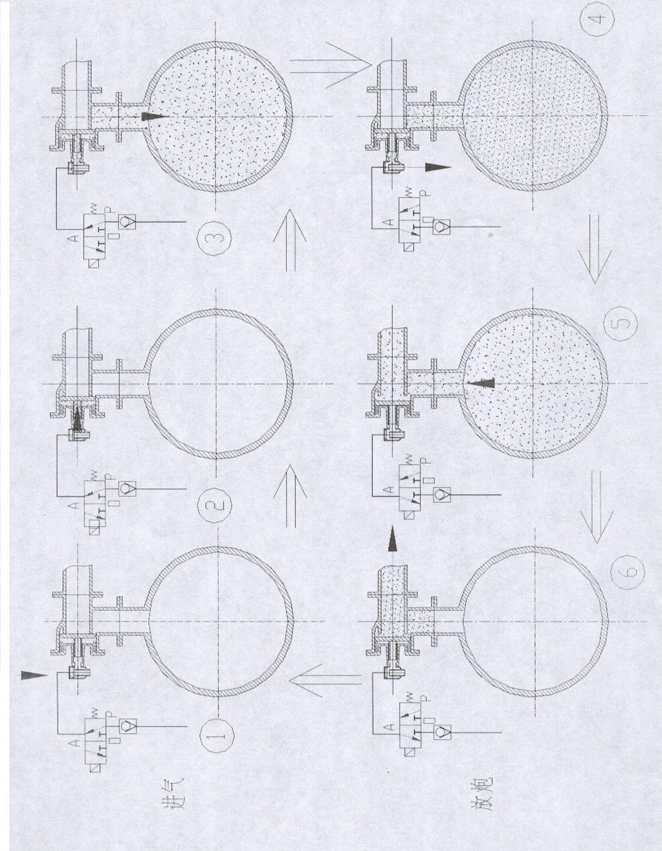

The principle is as follows:

1, air intake: open the intake valve, compressed air through the intake device into the gas tank.

After the inlet valve is opened, the three position two way solenoid valve is in the normally connected position, and the P-A communicates with the air inlet to press the first stage quick release valve diaphragm to seal the exhaust pipe, and rapidly release the piston cavity charging along the two edge of the diaphragm edge.

The piston of the two stage quick release valve is inflated in the piston chamber, and the piston movement is blocked by the spray tube, and the piston is inflated to the gas tank along the piston edge.

After the gas tank is filled with compressed air, the pressure in the cavity and the supply pressure are balanced, and the aeration is stopped automatically. The air gun is in the state of readiness.

2, detonation: in manual (or automatic) to give a signal to start the solenoid valve, air gun work.

Fourth, give a signal, three position two way solenoid valve in the power position of the P port is closed, A-O is a superior air release valve through the solenoid valve opening exhaust muffler O, chamber pressure decreased rapidly, the diaphragm on both sides lose balance. Under the action of air pressure, the diaphragm moves rapidly and releases the compressed air in the piston chamber of the two stage quick release valve.

After the rapid release of air pressure in the piston chamber of the two stage quick release valve, the piston is pushed to move and the jet tube is opened. The compressed air in the air storage tank is ejected in a very short time, and the energy is released, and the blockage area is cleared up.

3, reset

The solenoid valve and the power loss (or manual reset) after closing a quick release valve under the action of the air pressure tank at the same time, the air is released, two quick release valve at the lower part of the piston pressure decreases, the piston moves under the action of the spring force, seal the spray pipe explosion, began a new round of inflation process, according to the - the process cycle spray blasting operation.

5. Illustration of working principle:

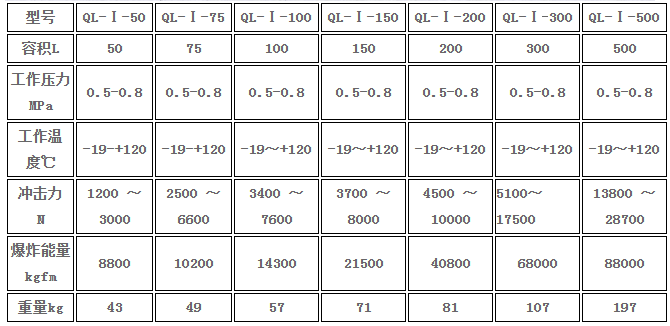

The air cannon size, has a very large impact point and the angle of incidence is sprayed into the air gun use effect, and material properties have a certain impact on the explosion removal efforts of different selected air gun specifications may not be the same, must be considered for the overall design and installation some factors. It is suggested that the company should guide selection and installation.

In a word according to the speed and degree of material properties, geometry, capacity and crust, scientific selection and arrangement of air gun.